M0NC/B13/28 Enthone Black Gloss Ink - 10cc Packet

M-Series inks may be applied by hand stamping, machine marking, screen printing, spraying and roller printing.

Size: 1/3 Ounce Bi-Pak

Color: Inorganic Black Gloss

Color: #17038 M-0-NC Has a Blue Tint.

Meets: CID A-A-56032D Types I, II & III, Non Conductive.

Formerly: MIL-I-43553b.

Catalyst: Comes with the B13/28 catalyst.

Characteristics:

Superior adhesion to epoxy, glass, metal or other nonporous surfaces

designed for rubber stamping or offset printing. Excellent resistance to

abrasion, MEK, alcohol, TCE, flux removers, salt, acid and alkali

solutions when properly cured. When used with a rubber stamp, use a

brayer roller or similar device to roll the ink into a thin drawn down

before transferring to the stamp.

Please let us know if you need the Glass Plate, and Roller, and the type of marking device needed to complete your order

MIXING INSTRUCTIONS

Measure ink and catalyst at the proper mix ratio. Both the ink and

catalyst should be weighed accurately. Excessive and insufficient

amounts of catalyst are detrimental to cured ink film properties. Mix

thoroughly without introducing excessive amounts of air. Avoid the use

of paper or wax coated cups. Stir from bottom of the container

OBSERVE INDUCTION PERIOD

All catalysts: 30 minutes

Catalysts 45 and 5: 60 minutes

Allow ink/catalyst mixture to stand for at least 30 minutes prior to

application. This provides an induction period ensuring a homogeneous mix

of resin and catalyst and allows any entrapped air to escape from the

mixture. The average pot life begins after the induction period.

COMMERCIAL ITEM DESCRIPTION

INK, MARKING, EPOXY BASE

Certified to MIL-I-43553 and AA56032.

The

General Services Administration has authorized the use of this

commercial item description (CID) as a replacement for MIL-I-43553B and

MIS-37271 by all federal agencies.

1.

SCOPE. This commercial item description covers a catalyzed epoxy system

of marking inks for metallic or other non-porous surfaces and printed

wiring boards.

2. CLASSIFICATION.

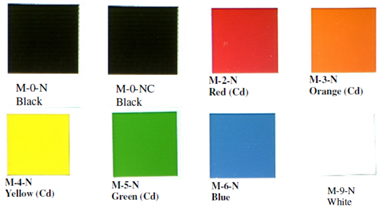

2.1 Type. The marking ink and color shall be of the following types and colors, as specified:

Type I - General usage

Type II - Non-conductive ink (e.g., printed wiring boards)

Type III - Outside exposure.

All other colors;

View SDS here;

Any questions call us at 714-979-1405 or email us at; Sales@HittMarking.com